HDPE (High-Density Polyethylene) sheets are an essential material widely used across various industries, from construction and packaging to agriculture and consumer goods. Known for their impressive strength-to-density ratio, flexibility, and resistance to chemicals, Polyethylene sheet price offer a range of benefits that make them a popular choice for numerous applications. This blog will explore what HDPE sheets are, their advantages, their uses in different sectors, and why they have become a go-to material in modern industries.

What Are HDPE Sheets?

HDPE sheets are made from high-density polyethylene, a thermoplastic polymer derived from petroleum. The process of producing HDPE involves polymerizing ethylene, which results in a plastic material that is both lightweight and durable. HDPE is highly resistant to impact, Plastic sheet hdpe, and various chemicals, which gives it a significant advantage over other types of plastics.

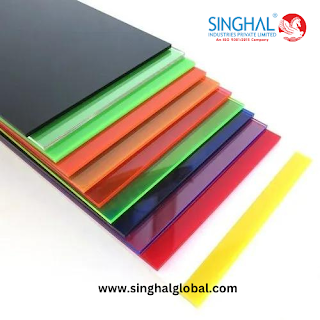

Typically, HDPE sheets come in various thicknesses and sizes, making them suitable for a wide range of applications. They are available in different forms, such as smooth, textured, or corrugated, allowing customization for specific needs.

Key Properties of HDPE Sheets

HDPE sheets possess several remarkable properties that make them a preferred choice for various industries:

- Strength and Durability

HDPE sheets are known for their high tensile strength, meaning they can withstand heavy loads and stresses without breaking or tearing. This makes them ideal for demanding applications like construction and heavy-duty packaging. - Lightweight

Despite their strength, HDPE sheets are surprisingly lightweight, which makes them easy to transport and handle. Their low weight is particularly beneficial in applications like packaging, where reducing shipping costs is crucial. - Chemical Resistance

HDPE sheets are highly resistant to a wide range of chemicals, including acids, bases, and solvents. This makes them suitable for applications where exposure to harsh chemicals is common, such as in chemical storage or industrial settings. - Water and Moisture Resistance

One of the standout features of HDPE sheets is their resistance to moisture. They do not absorb water, which makes them ideal for outdoor applications or in environments where they will be exposed to wet conditions, such as in agriculture and marine sectors. - Impact Resistance

HDPE sheets can absorb impacts without cracking or breaking, which makes them a robust choice for protective packaging, playground equipment, and construction materials. - UV Resistance

HDPE sheets can be treated to resist ultraviolet (UV) radiation, which means they can maintain their integrity and color even when exposed to sunlight for extended periods. This makes them suitable for outdoor applications.

Advantages of HDPE Sheets

1. Environmentally Friendly

HDPE is a recyclable material, which makes it an eco-friendly option compared to other plastics. It can be melted down and reused without losing its original properties, reducing the need for new raw materials and contributing to sustainable practices in industries that use plastic materials.

2. Cost-Effective

Compared to other materials like metal or wood, HDPE sheets are cost-effective. Their durability ensures a long lifespan, reducing the need for frequent replacements. This makes HDPE an economical choice for industries where cost savings are a priority.

3. Low Maintenance

HDPE sheets require minimal maintenance, which adds to their appeal. They do not corrode, rot, or deteriorate over time, making them a reliable material for long-term use in harsh conditions, such as in marine environments or construction sites.

4. Versatility

The versatility of HDPE sheets is one of their most significant advantages. They can be cut, shaped, and fabricated to meet the specific needs of different applications. Whether used as a lining material, a protective layer, or a structural component, HDPE sheets can be adapted for various purposes.

5. Hygienic

HDPE sheets are non-porous and resistant to mold, mildew, and bacteria. This property makes them an ideal material for applications where hygiene is crucial, such as in food processing, medical facilities, or water treatment plants.

Common Applications of HDPE Sheets

HDPE sheets are used in a variety of sectors due to their numerous advantages. Below are some of the most common applications:

1. Construction and Infrastructure

HDPE sheets are widely used in construction for a variety of purposes. They are often used as liners for landfills, ponds, and reservoirs, thanks to their water resistance and durability. In addition, HDPE sheets are employed as protective barriers in construction projects to prevent soil erosion and to provide reinforcement for foundations. They are also used in making temporary flooring, fencing, and retaining walls.

2. Packaging Industry

In the packaging industry, HDPE sheets are used for creating a wide range of products, such as bottles, containers, and protective packaging. Their impact resistance and durability make them perfect for packaging fragile goods. HDPE’s lightweight nature also makes it cost-effective for shipping, reducing overall transportation costs.

3. Agriculture and Aquaculture

In the agricultural sector, HDPE sheets are commonly used for lining irrigation systems, canals, and ponds. Their resistance to moisture and chemicals ensures that they can handle exposure to water and fertilizers without deteriorating. HDPE sheets are also used in the construction of greenhouses and livestock pens, offering protection from the elements.

4. Marine Industry

Due to their water resistance, HDPE sheets are ideal for marine applications. They are used in the construction of docks, boat parts, and fenders. Their ability to withstand the corrosive effects of saltwater and exposure to sunlight makes them a reliable material for long-term use in marine environments.

5. Playgrounds and Recreational Equipment

HDPE sheets are popular in the construction of playgrounds and recreational equipment due to their impact resistance and safety. They are used to create climbing walls, slides, and other playground structures. Their durability ensures that they can withstand the wear and tear of outdoor play while maintaining their appearance and functionality.

6. Automotive Industry

HDPE sheets are used in the automotive industry for manufacturing various components, including fuel tanks, liners, and protective covers. Their resistance to chemicals and impact makes them ideal for use in vehicles. Additionally, their lightweight nature helps reduce the overall weight of the vehicle, improving fuel efficiency.

7. Medical Industry

In the medical field, HDPE sheets are used to create hygienic surfaces and equipment. Their resistance to bacteria, mold, and moisture makes them suitable for use in hospitals and laboratories where cleanliness is essential. They are also used for making medical packaging and storage containers.

HDPE Sheets vs. Other Materials

When compared to other materials such as PVC, acrylic, or metal, HDPE sheets offer several advantages. For instance, HDPE is more flexible and impact-resistant than PVC, making it a better choice for applications where durability is critical. While metal may offer greater strength, it is more prone to corrosion and requires higher maintenance, whereas HDPE sheets are corrosion-resistant and require little upkeep. HDPE also offers superior chemical resistance compared to acrylic, making it more suitable for industrial and chemical applications.

Conclusion

HDPE sheets are a highly versatile, durable, and cost-effective material that has become indispensable in various industries. Their unique properties, including resistance to chemicals, water, impact, and UV radiation, make them suitable for applications ranging from construction and packaging to agriculture and medical use. Whether you are looking for a material to line a pond, protect packaged goods, or create a hygienic surface, Hdpe plastic sheet offer a reliable solution.

The widespread use of HDPE sheets can be attributed to their ability to adapt to different needs while providing long-lasting performance. As industries continue to seek cost-effective and environmentally friendly materials, HDPE sheets will likely remain a popular choice for years to come.

Frequently Asked Questions (FAQs):

What makes HDPE sheets from Singhal Industries ideal for construction projects?

HDPE sheets from Singhal Industries are highly durable, resistant to moisture, chemicals, and UV radiation, making them perfect for construction applications. Their strength and ability to withstand harsh environmental conditions ensure that they provide long-lasting protection, whether used for lining reservoirs, foundations, or erosion control. Additionally, their lightweight nature makes them easy to transport and install, reducing project costs and time.

How does Singhal Industries ensure the sustainability of its HDPE sheets?

Singhal Industries is committed to environmental sustainability by producing HDPE sheets that are fully recyclable. Their manufacturing process is designed to minimize waste and promote eco-friendly practices. HDPE sheets can be melted down and reused without losing their properties, making them an environmentally conscious choice for industries that prioritize reducing their carbon footprint.

What are the key applications of Singhal Industries' HDPE sheets in the agricultural sector?

Singhal Industries’ HDPE sheets are widely used in agriculture for lining irrigation canals, ponds, and greenhouses due to their excellent water and chemical resistance. These sheets help in efficient water management and protect crops from excess moisture or harsh weather conditions. Their durability ensures that they withstand continuous exposure to fertilizers and water, making them a reliable solution for long-term agricultural use.

.png)

Comments

Post a Comment